VRV 6A Series

- Dàn nóng đơn công suất lên đến 26HP

- Tiết kiệm năng lượng hơn với máy nén hiệu suất cao và điều khiển VRT Smart II

- Hộp linh kiện điện kín đạt IP55

- Thiết kế linh hoạt với giới hạn đường ống dài

- Chức năng nạp môi chất lạnh tự động giúp tiết kiệm thời gian

Thông tin sản phẩm

New Casing

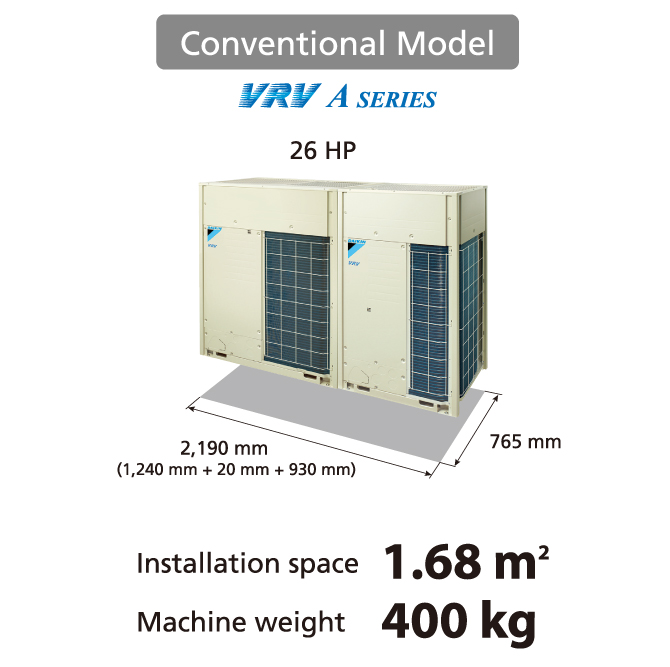

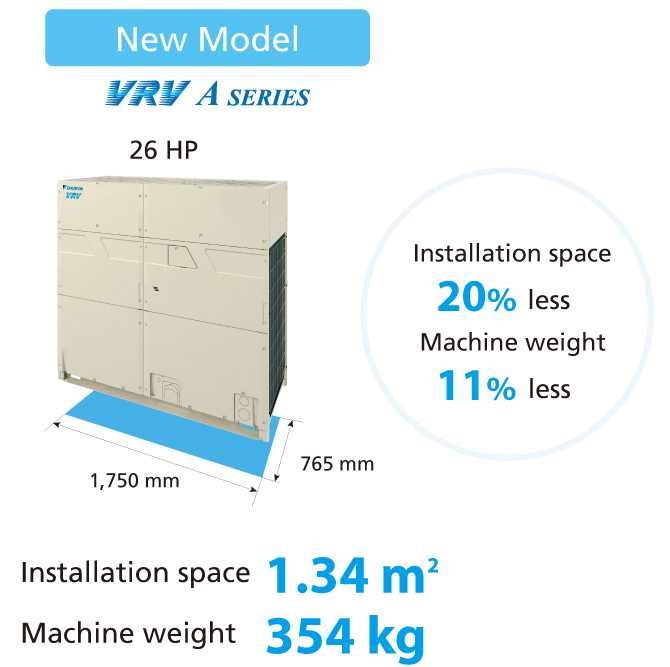

Large-capacity single module

The new large single unit casing reduces installation cost and space.

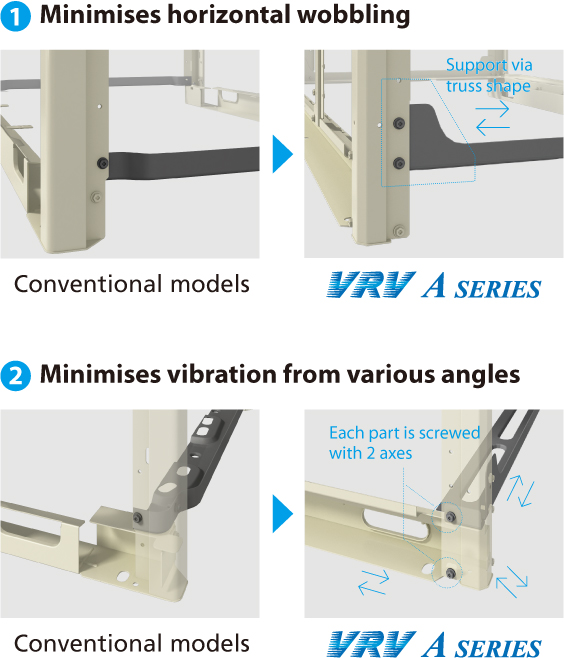

New reinforced design

The frame structure has been strengthened to improve resistance to earthquakes and wind while protecting against falling damage.

Energy Savings

Further energy savings have been achieved through the evolution of software and hardware technologies.

Software technology

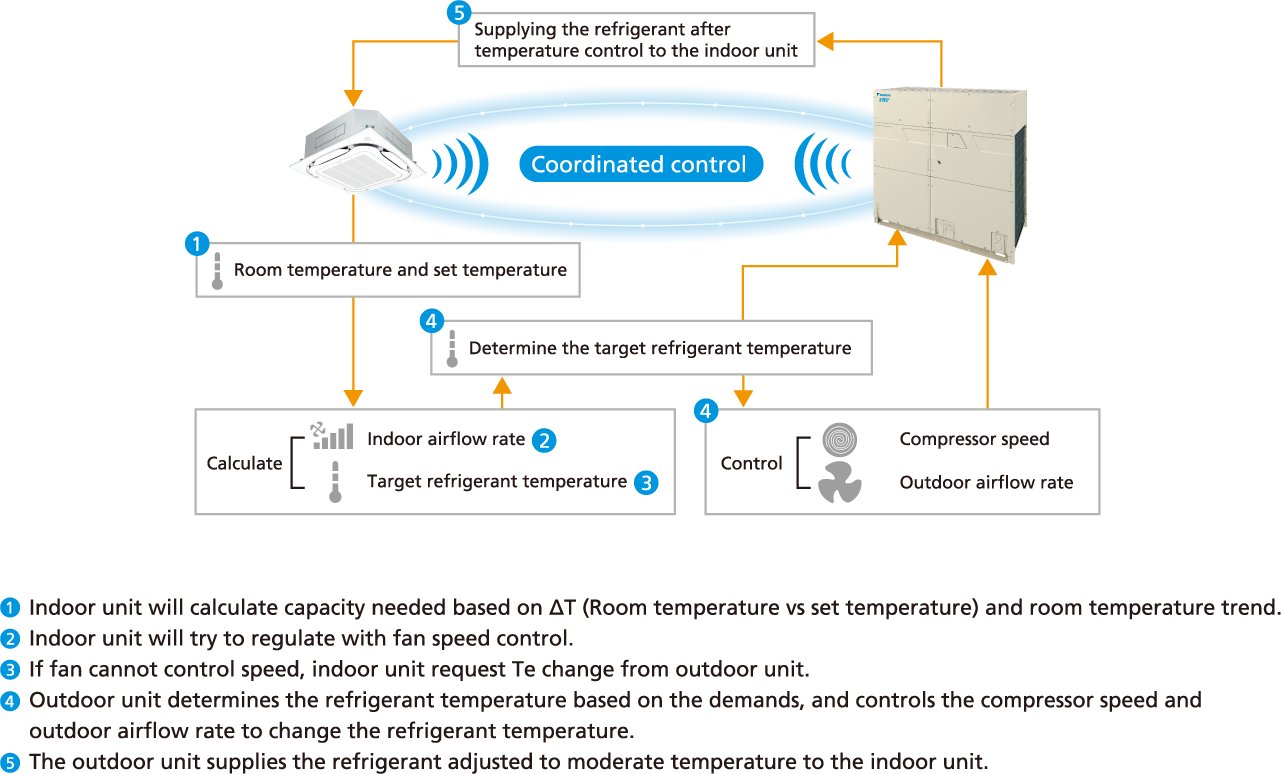

VRT Smart II Control

Optimal supply exactly meets the required capacity of indoor units

Further improvement of energy savings is achieved due to optimal control of the outdoor airflow rate.

Hardware technology

High Efficiency Compressor

New technologies increase seasonal efficiency and enable a compact design

Reliability

Designed to withstand hard environments.

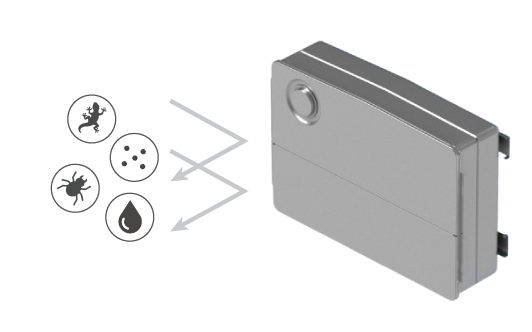

IP55 sealed electrical component box

IP55 sealed component box protects electrical component from a cause of failure, that is the ingress of debris (lizards, bugs, sand, water).

The internal mounting plate is hinged, enabling easy maintenance of the PCB on the back.

Gecko Experiment on the Electrical Component Box

To validate the reliability of our electrical component box, a controlled four-day gecko ingress test was conducted. The box was placed in an acrylic enclosure with 20 geckos and tested under 24-hour cycles. The results confirmed no gecko ingress, demonstrating the box’s robust design and protection against environmental factors.

Enables operation in high outdoor temperature

Three refrigerant cooling circuits enable stable operation even in high outdoor temperatures by suppressing a temperature rise for the PCB mounted in the sealed electrical component box.

Expanded operation temperature range

The outdoor operation temperature range is now extended from 49 to 52°C. This enables reliable operation even under high temperature conditions and a wider choice of installation locations.

IP55

IP55 is the degrees of dust and water protection for the electrical component box equipped on the product.

*The IP codes are classified and specified in the IEC standard (IEC 60529) for protection against dust and water.

Design Flexibility

Long piping length enhances design flexibility, enabling support for large buildings.

Long refrigerant piping

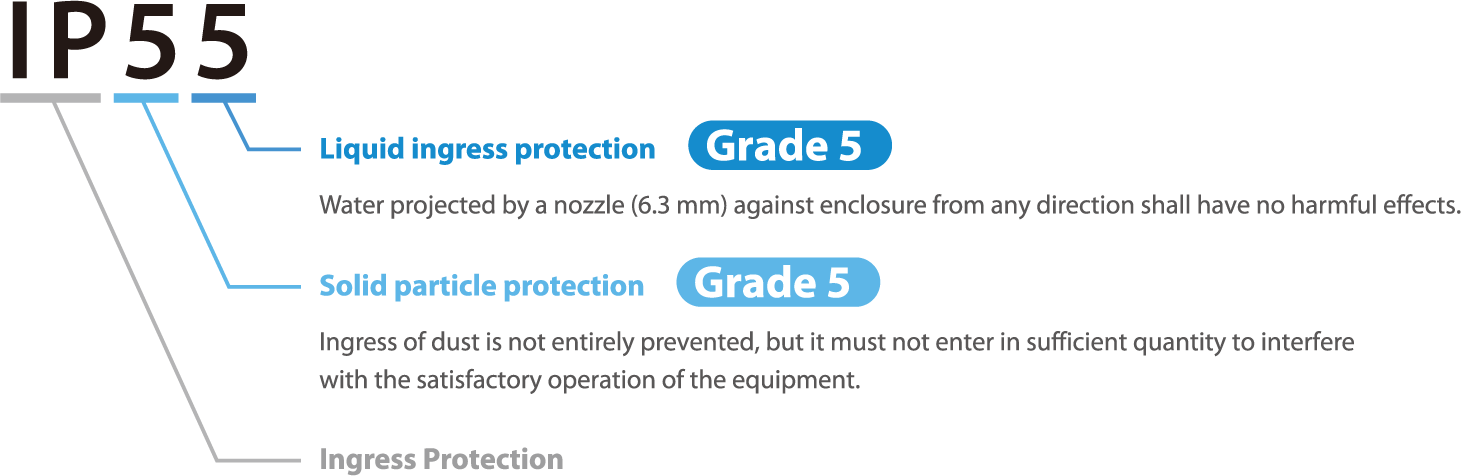

Simultaneous extension of height difference and equivalent length

Design flexibility is further improved by simultaneous extension of height difference, improved from 90 m to 110 m, and equivalent length (up to 190 m).

-

Height difference extension Max. 110 m

For height differences exceeding 50 m with the outdoor unit above the indoor unit and 40 m with the outdoor unit below, the main piping liquid piping size must be increased.

The operating temperature range is up to 49˚C (Outdoor units above indoor units only).

The minimum connection capacity index of the indoor unit shall be 63 or more (Outdoor units above indoor units only). -

Equivalent length extension Max. 190 m

When the equivalent piping length from outdoor unit to indoor unit is 90 m or more, be sure to increase the size of the liquid and gas pipes of the main piping.

* In addition to increasing the size of the main pipe, there are other piping restrictions regarding height difference extension and equivalent length. Check the Installation Manual for details.

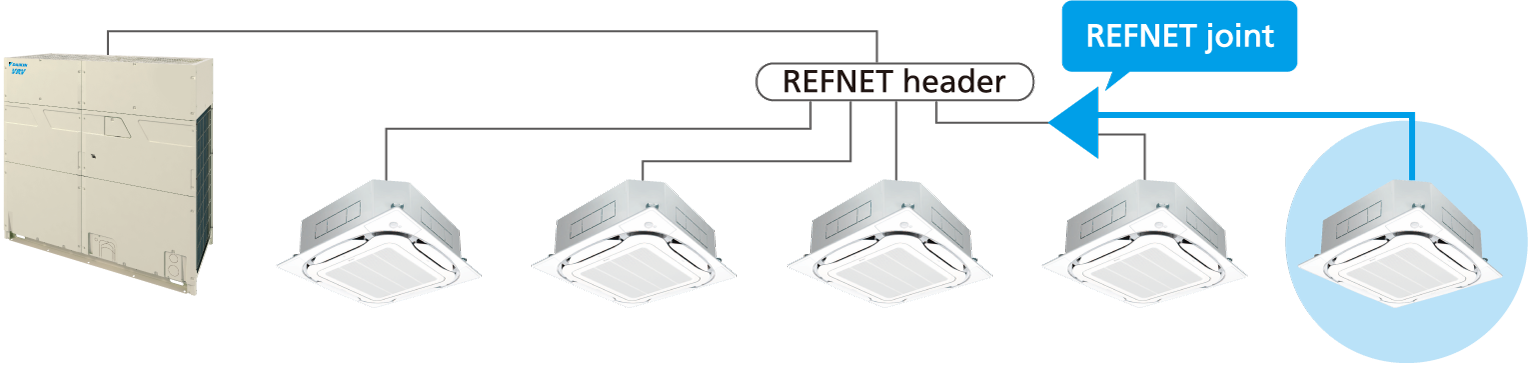

REFNET header downstream branching supported

Piping branch by REFNET joint is possible downstream of REFNET header.

The indoor unit arrangement can be more flexible.

Easy Installation

New structure improves installability.

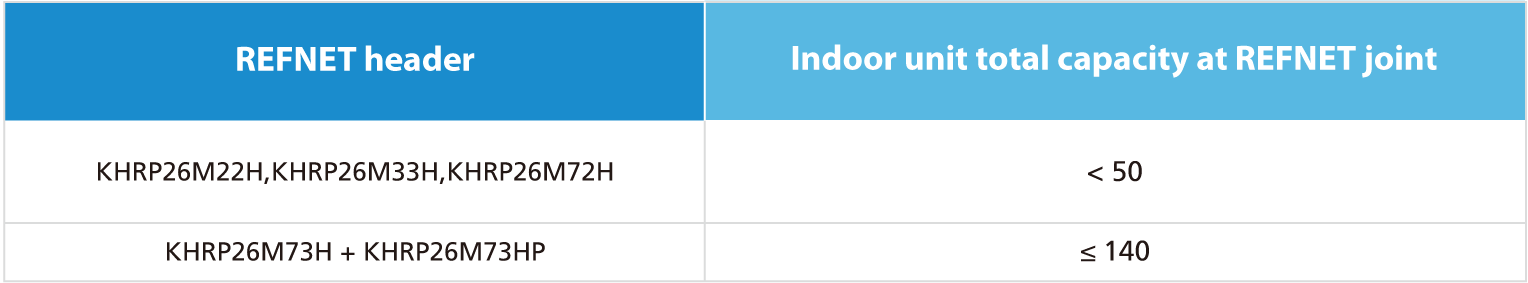

Automatic refrigerant charge function

Simultaneous extension of height difference and equivalent length

Contribute to optimised operation efficiency, higher quality and easier installation.

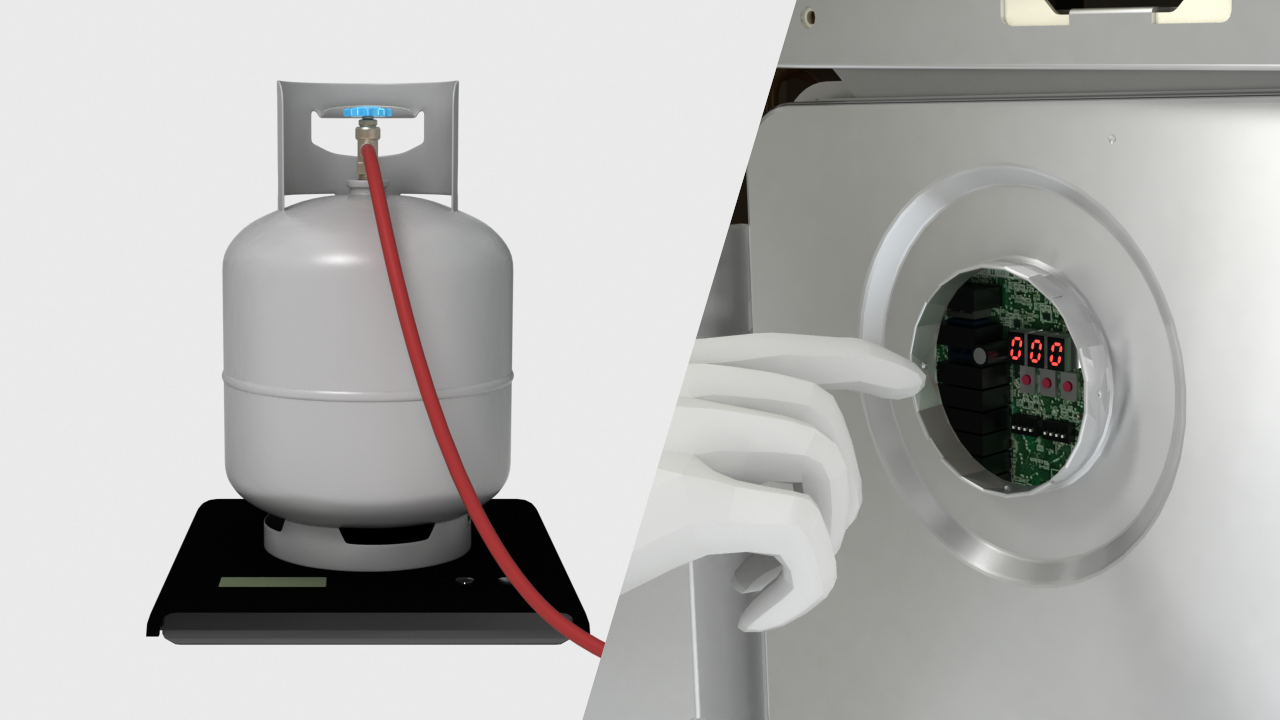

Electrical component service window

Main PCB 7-segment LED and setting buttons can be accessed without removing the front panel. This greatly improves workability during on-site setup or testing and enables quick error code checks during servicing.

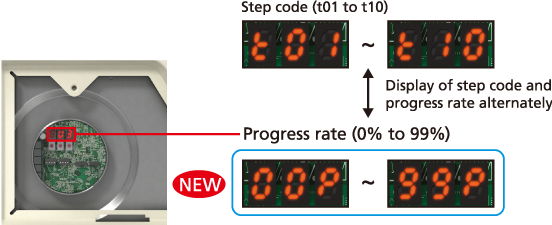

Process visualization (Test run only*)

In the new models, in addition to the actual step (t01 to t10), a progress rate (0% to 99%) is available as a guideline when making arrangements for on-site work.

* Effective when test run is carried out independently after manual refrigerant charging.

Improved refrigerant piping workability

By dividing piping and wiring holes to the left and right, piping and wiring work can be easily performed on site.

Comfort

Suppresses the nighttime operating sound to maintain the quiet environment.

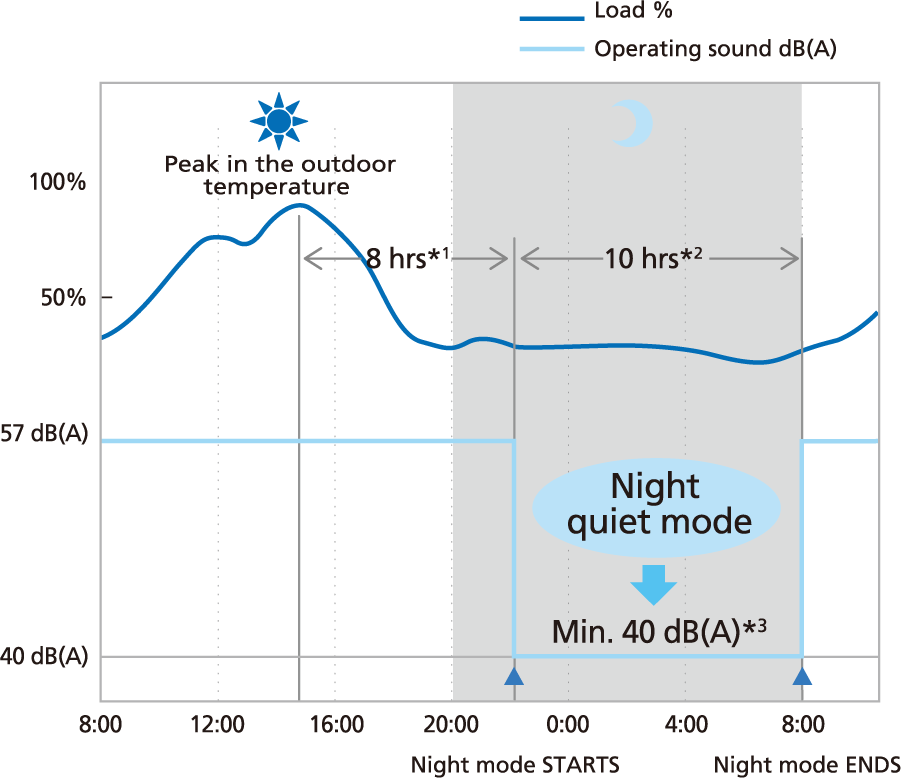

Nighttime quiet operation function

The nighttime quiet operation function automatically suppresses the nighttime operating sound by reducing operation capacity to maintain the quiet environment of the neighborhood.

Three modes are available to adjust the level of noise reduction.

- *1. Initial setting is 8 hours. Can be selected from 6, 8 and 10 hours.

- *2. Initial setting is 9 hours. Can be selected from 8, 9 and 10 hours.

- *3. In case of 8-12 HP outdoor unit.

14-26 HP outdoor unit can maintain ≥ 30% of the rated capacity with the sound < 44 dB(A).

Notes: This function is available in setting at site.

The operating sound in quiet operation mode is the actual value measured by our company.

The relationship of outdoor temperature (load) and time shown above is just an example.

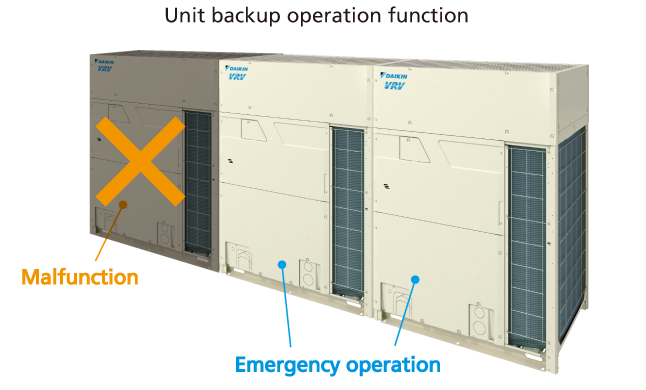

Backup operation function

In the event of a failure, the emergency operation can be activated, allowing the remaining system to continue functioning. If one unit in a multi-unit outdoor system fails, the others will maintain emergency operation until repairs are completed.

Engineering Support

Design assistance and sales proposal

Đánh giá

Chưa có đánh giá nào.